Plexiglas Martian Chessboard Sections

Nicer Tri-Chess

July 2002

July 2002

In November of 2000, Andrew Bergstrom walked into the Pop-Tart Cafe at Philcon with a stack of Martian Chessboard Sections that he'd made from Plexiglas. He had the wedge shapes laser cut, and he'd painted the backs of the boards by hand to acheive the pattern and whatever color he wanted. Then, he'd covered the backs with felt to protect the paint and make the boards slide easier on a table. They were terrific, but he only had a small quantity, and he quickly sold out of them.

So quickly did he sell out, that I didn't actually get any. He also hasn't been able to make any since then. That's OK though. Since it was my design to start with, I figured I could re-create his process, and maybe improve upon it.

After thinking about it for a long time, I settled down to actually make some. It was easier than I thought, since I started with a printout instead of having to paint the design by hand. I made a test run, then set about designing a process to mass-produce the boards. Hopefully, I'll be able to offer some for sale.

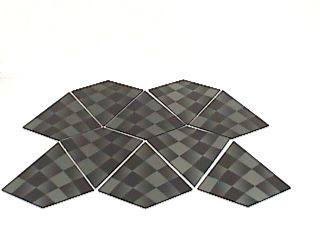

The picture above shows six from the first batch. The gray ones are made from Plexiglas that I (still) had left over from another project. the white ones are made from clear plexi that I bought in a framing store. I tried regular soft felt from the craft store, but soon realized I could use a more heavy-duty type of felt that is stiffer and won't wear off as quickly.

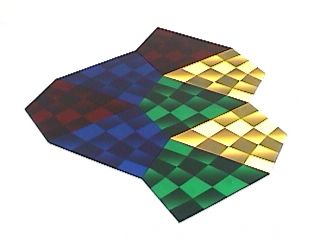

For this batch (August 2002), I used colored plexiglas. The red is a little dark, but the yellow is positively stunning. I started with 12" squares of plexi that I bought at one of the Philadelphia plastics stores that sells scrap. Dale also had some irregularly shaped pieces. Next time I'm in one of those stores I'm going to get a pile of different colors. The plastic is more expensive this way, but I really like the results.

This batch tests out my method for producing plexiglas boards in mass quantities. I actually bought a full sheet of plexi and had it cut into 40 rectangles (I can get two boards from each rectangle). I made these ten in two tries. The first try I only made two boards, and it took about an hour. The second try (September 2002) I made eight and it took less than an hour. If I can get to the point that I can make a dozen or so of them in an hour, I should be able to sell these for a reasonable price.

Update, October 2002: I completed the mass production project and have a big pile of boards now, enough that I can start selling them. Please see the store page for more information on prices and ordering. I estimate that I spent maybe ten hours doing all the work, which isn't bad. This was spread over several weeks, but it's good to know that if I ever need to make a bunch of these I really only need a couple of days.

Some notes on the above:

[You can purchase these boards!]

[You can purchase these boards!]